SWAAT海水循环醋酸腐蚀试验箱

摘要:SWAAT腐蚀试验主要是以一种用合成海盐代替传统的氯化钠的腐蚀试验,然后用冰醋酸将溶液酸化。符合标准:ASTM G 85海水醋酸试验、PV 1208。 |

SWAAT海水醋酸腐蚀试验箱

1 Scope .

This Test Specification describes a procedure for evaluating the corrosion resistance of heat exchangers (e.g., condensers, evaporators and water, oil and charge air coolers), and other components made of aluminum alloys .本试验规范描述了评价热交换器耐腐蚀性的程序( 例如冷凝器、蒸发器和水、油和充气空气冷却器)以及其他由铝合金制成的部件。

2 Designation

SWAAT test according to PV 1208

3 Requirement

The components must withstand the required testing without leakage.

The brazed joints, e.g, between flat tube and cooling fin, must have no separations over large areas.

Slight selective corrosion of the fller metal is permissible .

Uniform surface erosion and shallow pit corrosion with a low corrosion depth (< 30% of the material thickness) are permitted; however, pitting and other corrosion types such as intercrystalline corrosion on fluid- or gas-bearing parts are not.

The required cycles are to be taken from the Technical Supply Specifications and/or drawings for the individual components.

In principle, the components are inspected with the bright or passivated finish.

The required minimum for complete testing is 5 parts.

组件必须经受住所需的测试而不泄漏。

钎焊接头,例如扁平管和冷却翅片之间,必须在大面积上不分离。允许对填料进行轻微的选择性腐蚀。均匀的表面 侵蚀和低腐蚀深度浅点蚀( <材料厚度30%)是允许的;然而,点蚀等腐蚀类型如晶间腐蚀流体或气体轴承零件不。所需的周期是从技术供应规格和/或图纸的各个组成部分。原则上,这些部件经过光亮或钝化处理。完成测试所 需*低限度是5个部分。

4 Testing

4.1 Procedure

The procedure is an accelerated corrosion test with a cyclically sprayed aqueous acetic acid sodium chloride solution as the corrosive medium. It is known as the“Sea Water Acetic Acid Test". The test is carried out in a test chamber according to DIN 50021 on finished parts and evaluated under a microScope using transverse metallographic microsections. The heat exchangers are subsequently tested for leak tightness. The corrosion load occurs in principle from the outside. A simultaneous pressure load is not performed during the test

该程序是用循环喷射的醋酸氯化钠溶液作为腐蚀个质进行加速腐蚀试验。它被称为“海水醋酸试验”。进行测试,在试验室根据DIN 50021对成品进行显微镜下采用横向金相磨片。随后对换热器进行了气密性试验。腐蚀负荷在原则上是从外部产生的。试验期间不执行同步压力负荷。

4.2 Leak tightness test

Prior to the corrosion test, the components must be tested for leak tightness. All open connectionsmust be sealed prior to the corrosion test (e.g, using rubber plugs or plastic caps).

在进行腐蚀试验之前,必须对部件进行气密性试验。所有打开的连接必须在腐蚀试验之前密封( 例如,使用橡胶塞或塑料

盖).

4.3 Test solution

The test solution is made from analytically pure table salt (NaCl, purity grade according to German Pharmacopoeia DAB 7), de-ionized or disilled water and acetic acid (purity grade according to DAB 7). For preparation, 42 g NaCI and 10 ml anhydrous acetic acid per liter of solution are used. The pH level of the solution is adjusted with NaOH (purity grade according to DAB 7) so that both the spray solution and the collected condensate have a pH level of 2.8 to 3.0. The measurement is performed electrometrically at (25±2)。C with a glass electrode

测试溶液是由分析纯食盐(NaCl, 纯度等级根据:

德国药典DAB 7)、去离子水或蒸馏水和乙酸(纯度等级根据DAB 7)。制备、NaCI 42克和10毫升无水乙酸每升溶液中使用。溶液的pH值用NaOH (根据DAB 7的纯度分级)调节,使喷雾溶液和收集的冷凝液的pH值为2.8至3。进行测量电势滴定来在(25+2) 。C用玻璃电。

SWAAT腐蚀试验主要是以一种用合成海盐代替传统的氯化钠的腐蚀试验,然后用冰醋酸将溶液酸化。符合标准:ASTM G 85海水醋酸试验、PV 1208。

技术要求:

1. 收集液PH值范围:2.8~3.0

2. 测试箱温度:49℃

3. 饱和桶温度:57℃

4. 喷雾压力98kpa

5. 测试周期:30分钟喷雾-90分钟冷凝水一天12个循环

满足试验标准及测试方法 :

1.GB-T10125-2012人造气氛腐蚀试验 盐雾试验

2.ASTM/B117-2011盐雾试验

3.GB-T5170.8-2008_电工电子产品环境试验设备检验方法___盐雾试验设备

4.GJB150.11A-2009 军用装备实验室环境试验方法盐雾试验

5. GBT2424.17-2008 盐雾试验方法

6.GJB150.11_1986盐雾试验

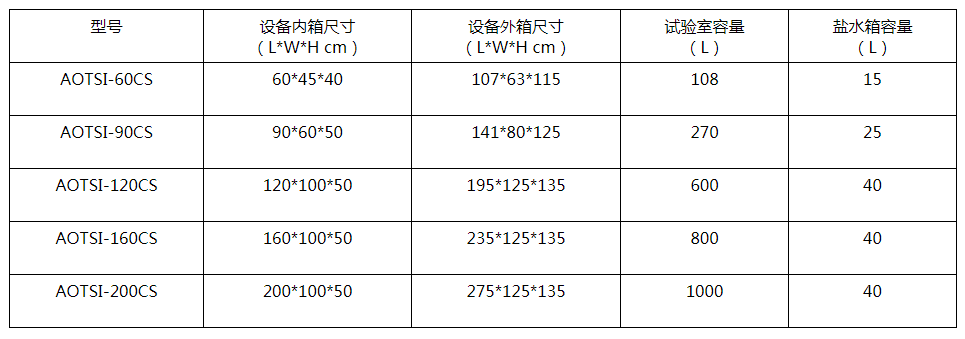

产品规格:

*注:可依客户产品尺寸定制

本文出自东莞市澳腾斯仪器有限公司,转载请注明出处!更多澳腾斯地板类检测设备相关资讯请访问:www.aotsichina.com

24小时热线电话:13712277050

热门搜索:

热门搜索: